Metal Roofing

PFAS are used as protective coatings for metal sheet roofs, metal shingles, flashing, and roofing nails. PVDF and FEVE are two fluoropolymer PFAS commonly used in this type of application.

Persistent and pervasive

PFAS are used in numerous types of building products. While PFAS serve desirable functions such as weatherproofing, corrosion prevention, and stain resistance, their utility comes at a cost to health and the environment.

We collected information on PFAS uses in the built environment from company websites, patents, peer-reviewed literature, and more. Our Building a Better World report summarizes this information and proposes a path forward to reducing PFAS use in building materials. Building owners, architects, designers, contractors, manufacturers, and regulators are encouraged to identify and eliminate non-essential uses of PFAS in buildings.

Read the full report here.

View our webinar recording on PFAS in building materials here.

The following list is not exhaustive. PFAS use may be more or less common within any of the categories below.

Jump to:

PFAS are used to resist weathering and prolong a roof's useful life as well as to reflect solar radiation and keep building interiors cool.

PFAS are used as protective coatings for metal sheet roofs, metal shingles, flashing, and roofing nails. PVDF and FEVE are two fluoropolymer PFAS commonly used in this type of application.

PFAS may be used to coat asphalt shingle granules to increase the solar reflectivity of roofs and keep buildings cooler.

Weatherproofing membranes for flat and low-slope roofs may contain PFAS.

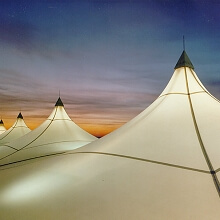

PFAS are used to create decorative textile-based roofs, also known as tensile roofs.

PFAS coatings may be applied to rain gutters and concrete roofing tiles to repel dirt and resist staining and mildew.

PFAS may be added to paints to improve flow, spread, and glossiness, and to decrease bubbling and peeling. They are also used in specialty paints to give stain-resistant, graffiti-proof, and water-repellent properties. PFAS are also used in powder coats.

PFAS are employed as metal coatings to protect against corrosion, staining, and weathering and to increase solar reflectivity. Most PFAS-containing metal coatings are applied during fabrication of the metal. PVDF and FEVE are two fluoropolymer PFAS commonly used in this type of application.

PFAS are added to wood lacquers and sealers as wetting agents. They are also used to enhance stain resistance and oil and water repellency.

PFAS may be used as coatings for a variety of plastic products including bathtubs, doors, countertops, and white boards.

PFAS were used extensively as stain, soil, and water repellents in carpets and rugs. Fortunately, PFAS-free carpets and rugs are now widely available.

PFAS are sometimes used to add stain and soil repellency to resilient flooring. PFAS are more commonly used as leveling and wetting agents in after-market floor protectors, finishes, waxes, and polishes.

PFAS are used in surface sealers for stone, tile, grout and concrete to increase resistance to oil, water, and stains. For sealers used on exterior surfaces, PFAS are also used to protect against graffiti and limit buildup of snow and ice. Alternatives to PFAS exist - read our blog for more details.

PFAS are added to some caulks to increase durability and chemical resistance.

O-rings used for high-pressure, high-stress, and high-temperature applications can be made of PFAS.

PFAS are added to adhesives to increase wettability and penetration of the substrate, resulting in a stronger bond.

PFAS are used to make glass and ceramic surfaces more durable, to prevent soiling and grime, and to provide "easy to clean" and anti-smudge characteristics. Windows, mirrors, shower doors, bathtubs and toilets may be coated with PFAS.

Fluoropolymer coatings are applied to “shatterproof” light bulbs advertised for laboratory, medical, and consumer uses. They reportedly increase the durability of bulbs and impart non-stick and easy-clean characteristics.

PFAS are added to furniture fabrics to impart them with stain-, soil-, and water-repellent properties. PFAS can be applied to individual fibers or finished fabrics during manufacturing, or as after-market treatments.

PFAS are used as insulation in some electrical wires and cables. PFAS reportedly allow for the use of thinner insulating sheaths that are flexible, durable, and resistant to heat.

Plumber’s tape, also known as thread-seal tape, is used to seal pipe connections and other threaded fittings. Plumber's tape is often made of PTFE, a type of fluoropolymer PFAS.

PFAS-containing fiberglass and film tapes are used in electrical applications such as wrapping bundles of wires that run between separate floors of commercial buildings.

PFAS may be used in flashing tape for sealing doors and windows to the frame of a building. PFAS may also be used in tape for holding together the frames of windows, doors, and other building openings during manufacturing.

PFAS have been detected in composite wood products like oriented strand board, medium and high density fiberboard, and plywood, as well as wood fiber insulation. The source of the PFAS may be adhesives used in these products.

PFAS coatings or films can be used in several components of solar panels. PFAS reportedly increase durability, transparency, mechanical strength, and resistance to UV, heat, and dirt. PFAS are used in the rechargeable batteries that store the energy captured by solar panels.

PFAS may be used as an extrusion aid during the manufacturing of artificial turf blades. PFAS have also been detected in backing of artificial turf.

PFAS are employed in seismic dampers used to make large buildings and bridges resilient to earthquakes. Pads or discs made of PFAS are used in a variety of ways to seismically reinforce structural skeletons and foundations.